Heavy Duty Strip-Till Row Units with Advanced In-Field Control

- Advanced hydraulic control to achieve the ideal strip across highly variable field conditions with minimal HP demand

- Hi-tensile steel construction with laser precision for unrivaled durability, serviceability, and consistency

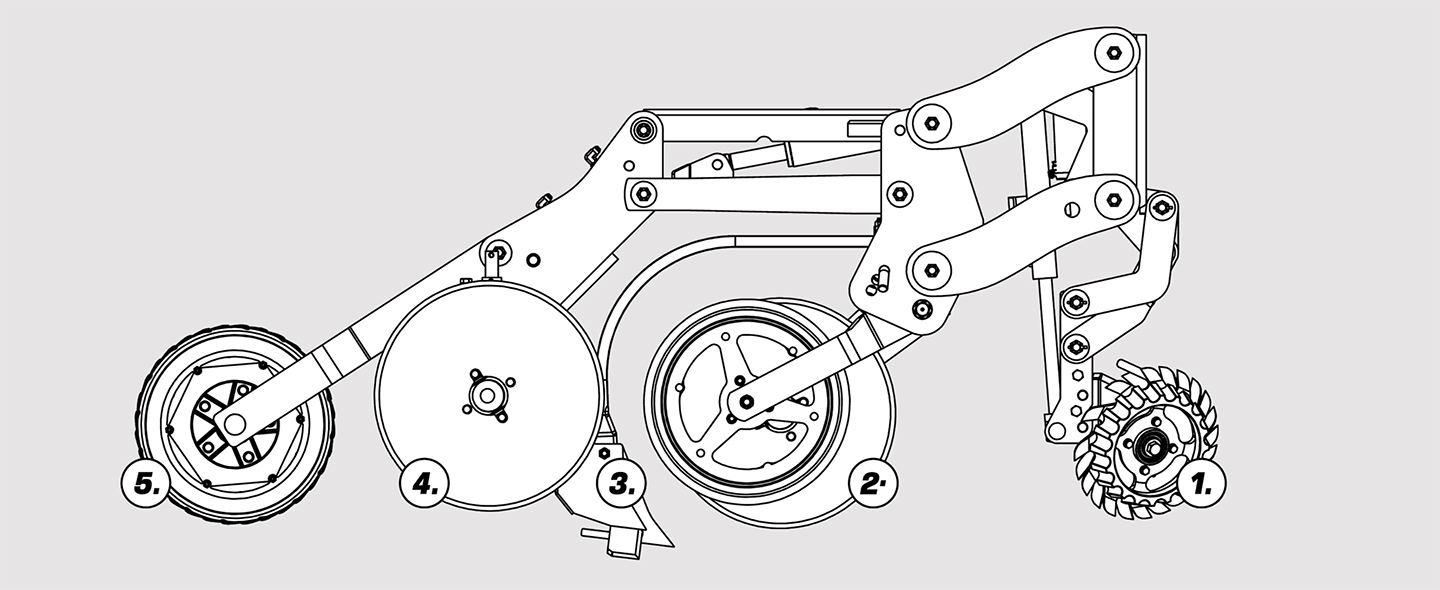

Featuring 5 Zones of Action

1. Row Cleaners

Hydraulic up/down force control for accurate trash clearing ahead of the strip creation. Patented LaserSweep docking station allows for different angle row cleaner to be easily swapped for different row spaces, light or heavy trash conditions & different styles of cleaning disc blades.

2. Coulters

Independent adjustment allows coulter to be set to different depths based on crop residue on the soil surface. Proper cutting of residue is essential to ensure in-line tillage knife does not become clogged with residue buildup. Hydraulic up/down force system to maintain proper penetration of hard or soft soils.

3. In-Line Tillage Knife

Spring steel “mini-shank” with in-line angled tillage knife designed to lessen compaction while going deep enough to destroy cover crop roots to mitigate regrowth. Provides ideal root-zone placement for fertilizer application. Hydraulic up/down force maintains proper penetration of hard or soft soils. In-line tillage knife depth controlled by gauge wheel.

4. Berm Building Discs

Adjustable spacing & angle. Will cover applied fertilizer for environmental control & build a berm for future seedbed. Hydraulic up / down force controls pressure applied to the berm building discs. Parallel linkage maintains disc angle to ensure uniform berm building & applied fertilizer coverage.

5. Firming Wheel

Firms the soil berm to help prevent moisture and wind erosion. Hydraulic up/down force applies constant necessary firming pressure. Interchangeable with rolling basket.